Once the hull had been made sound and the droughts securely bolted to the new frames and the listings or listons relaced, work could start on repainting her on the outside and the inside attended to.

First of all the floorboards needed replacing and the same time the engine box needed some attention and it was decided to replace it completely to make it much easier to move around while trying to sail her. – MD 21-Apr-24

Fitting Out – per Fred Crowell

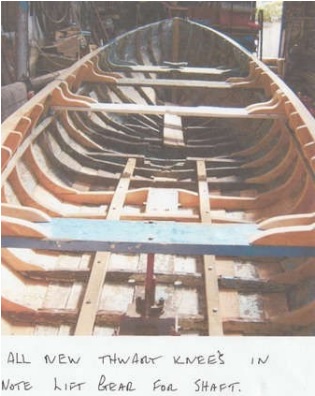

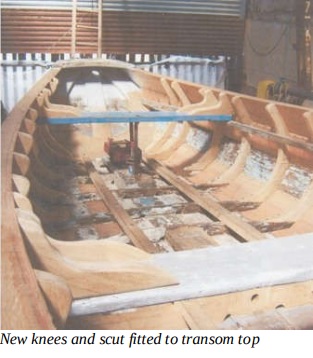

Now we start to refit the thwarts and fit the new knees these are cut with care to get the grain right. If not cut correctly these will fail at the short grain section. These will be fixed through the gunwhale as other fixings, with galvanized nails.

The working boats tend to use steel knees 2 inch x 1/2 flat bar with a 3/4 inch round bar welded on to form a triangle from gunwhale to thwart, this gives a very strong job and also the bar gives a tying up point for ropes fenders etc. The midship thwart on the larger boats usually has a bulkhead constructed on the aft edge this adds some strength but also creates a separation from the engine area and the working area.

The thwart midships and next forward usually have a plywood board resting between them this creates part of the engine cover also makes getting forward much easier.

Page 17.